To extend storage period and shelf life and reduce waste, it is adviced to drench the fruits and vegetables with water and fungicides.

There are 3 drencher models:

I. Cabinet drenchers

This is the most economic model among other models. There is a cabinet which is divided into 2 sections. Pallets of fruits are washed in sequence. A pneumatic driven door, opens one section and lets the forklit put a pallet into the section and close the other section and starts the washing cycle. A pump circulates the water from the tank to the washing nozzles. Capacity: 20 pallets/hour

This is the most economic model among other models. There is a cabinet which is divided into 2 sections. Pallets of fruits are washed in sequence. A pneumatic driven door, opens one section and lets the forklit put a pallet into the section and close the other section and starts the washing cycle. A pump circulates the water from the tank to the washing nozzles. Capacity: 20 pallets/hour

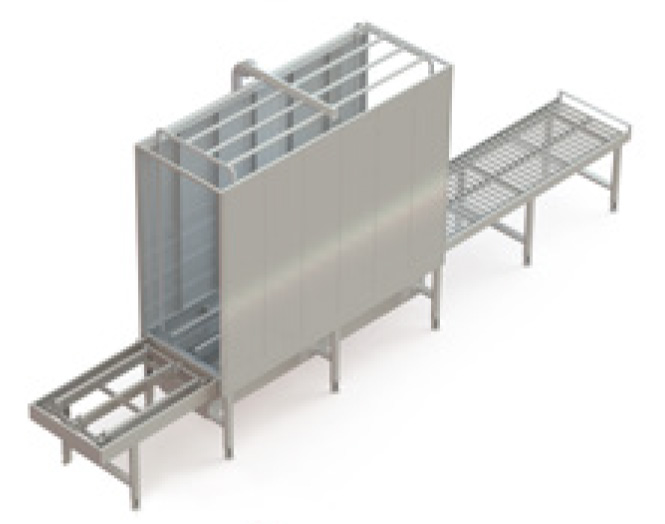

II. Chain conveyor drenchers

This is a continuous drencher. Pallets of fruits travel on chains. This type of drencher is composed of 3 sections. The feeding section is 2 meters long, the washing section is 4 meters long and the waiting section is 4 meters long. In the washing section, a centrifugal pump sucks the water from the tank and presses it to the pipes and nozzles. Nozzles can wash the pallets of boxes both from the top and from the sides. At the waiting section, water flows back to the tank and it reduces the water consumption. Capacity: 40 pallets/hour

This is a continuous drencher. Pallets of fruits travel on chains. This type of drencher is composed of 3 sections. The feeding section is 2 meters long, the washing section is 4 meters long and the waiting section is 4 meters long. In the washing section, a centrifugal pump sucks the water from the tank and presses it to the pipes and nozzles. Nozzles can wash the pallets of boxes both from the top and from the sides. At the waiting section, water flows back to the tank and it reduces the water consumption. Capacity: 40 pallets/hour

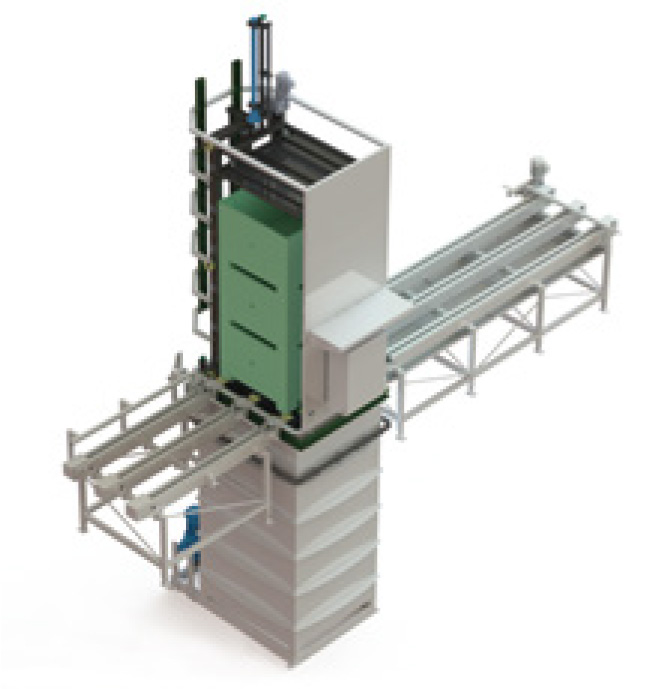

III. Dipping drenchers

The dipping drencher is the most advanced type of drenchers. The complete pallet submerges into water and best contact is achieved between fruits and fungicides. The feeding and the waiting sections are identical to chain conveyor drenchers. A hydraulic driven lift system carries the pallets in and out of the water tank. The washing time can be adjusted. Capacity: 50 pallets/hour

The dipping drencher is the most advanced type of drenchers. The complete pallet submerges into water and best contact is achieved between fruits and fungicides. The feeding and the waiting sections are identical to chain conveyor drenchers. A hydraulic driven lift system carries the pallets in and out of the water tank. The washing time can be adjusted. Capacity: 50 pallets/hour